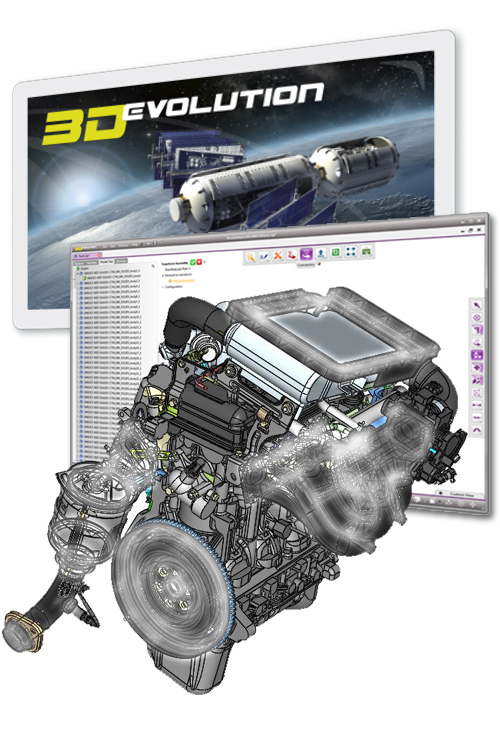

3D_Evolution

3D_Evolution Software, CoreTechnologie Software

How Does it Work?

3D_Evolution software streamlines the process of CAD data conversion, supporting 24 major formats without the need for a separate CAD license. It's designed to be fast, accurate, and equipped with advanced data healing capabilities. This ensures the creation of VDA and SASIG-certified models, elevating MCAD interoperability.

Handling Daimler JT data, including PLMXML and STEP AP242 structures, is made simple with 3D_Evolution. The JT Supplier Module facilitates an effortless certification and data exchange process. Being Daimler-certified, the software supports all JT Daimler criteria and can efficiently manage very large assemblies, ensuring optimal model quality through automatic healing.

Feature-based conversion in 3D_Evolution is a unique technology. It enables the transformation of CAD data into fully functional models, retaining complete history and parametric details. Compatible with CATIA, NX, CREO, SolidWorks, and Inventor, it delivers 100% operational CAD models. This exceptional versatility makes it a valuable tool in various engineering applications.